Your cart is currently empty!

ABOUT ORF BIOLOGICS

Advancing science using synthetic biology and proprietary biologics manufacturing platforms to drive research and therapeutic breakthroughs.

Advancing Complex Protein and Antibody Manufacturing

Off-the-Shelf and Custom Protein Manufacturing to Address Complex Challenges

We utilize powerful and proprietary expression systems to provide the highest quality peptides, proteins and antibodies. Our technology enables precise control over protein function and bioavailability while supporting scientists in meeting their specific research needs.

Modular Workflows for Accelerated Biological Design

Our modular synthetic biology workflows are designed to simplify experimentation, speed up prototyping, and foster collaboration. By standardizing parts and processes, we make it easier for the scientific community to share knowledge and build on each other’s discoveries.

Pilot-Scale Infrastructure for Real-World Impact

We offer pilot-scale production infrastructure that bridges the gap between lab discovery and industrial application. Our platform supports researchers, biotech innovators, and pharma leaders in tackling real-world biomanufacturing challenges, including downstream processing and resource limitations—especially for small and growing companies.

OUR COMPANY

Market-Aligned Innovation from Lab to Launch

Located in the Heartland of America, we pride ourselves on pioneering next-generation biologics. What sets us apart is our ability to manage the entire process—from initial design to the final protein delivery. We take pride in our in-house innovation, constantly striving to develop solutions that meet the evolving needs of the industry. By closely monitoring market trends, we identify and address emerging demands, ensuring that our solutions are both cutting-edge and impactful for our partners.

OUR EXPERIENCE

Our scientists possess the practical expertise required to take ideas from the bench to the bioreactor and ultimately to a purified product.

This wealth of knowledge empowers our team to tackle critical needs within the scientific community while also addressing the broader demands of customers. Our deep understanding of the biomanufacturing process enables us to deliver solutions that not only drive innovation but also meet the practical challenges faced by industries and end-users alike.

Development

Our biologics development process combines cutting-edge synthetic biology with advanced computational tools to design proteins from concept to sequence. We then select the best expression system for efficient production, ensuring purity and functionality. From initial design to final delivery, we provide a streamlined and integrated solution, offering a seamless transition through each stage of development for reliable, ready-to-use biologics.

Designing Proteins with Synthetic Biology

Using advanced computational tools, we design proteins from concept to sequence to finished product, creating synthetic biology solutions for specific applications. Once finalized, the design is ready for sequence generation and expression.

Expression and Purification

After selecting the optimal expression system, we produce and isolate the protein, ensuring purity and functionality. The final product is carefully separated and prepared for shipment.

From Concept to Delivery

We provide a seamless workflow from designing novel proteins to delivering a ready-to-use product, covering every stage of development within a single, integrated process.

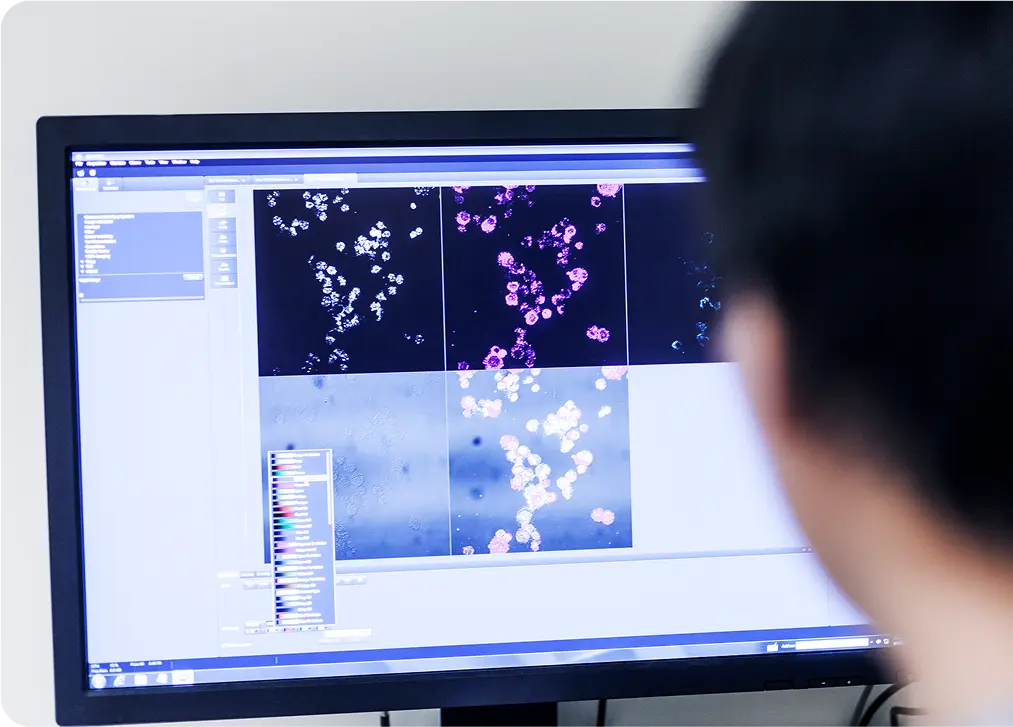

Manufacturing

Our biologics manufacturing process begins with high-quality DNA production and utilization of the most appropriate expression system. We then select and expand the best-performing cell lines for optimized, stable protein production. As part of our scalable approach, we offer large-scale protein expression capabilities and cell banking solutions to maintain reliable, long-term production readiness, ensuring consistency and quality for therapeutic development.

DNA Design and Process Optimization

We produce and purify high-quality DNA and then introduce it into the appropriate host system to drive gene expression.

Clone Selection & Optimization

After the introduction of the DNA, we identify and expand the most promising cell lines to ensure stable, high-yield protein production for research and therapeutic applications.

Scalable Production & Storage

Engineered cells are optimized for large-scale protein expression, with options for cell banking to preserve and maintain production-ready lines for future manufacturing.

Testing

Our comprehensive biologics testing process ensures protein quality at every stage. We perform in-process testing to monitor production and verify accuracy, followed by final product assessments to ensure performance and bioavailability for therapeutic use. Additionally, our stability and viability testing evaluates protein degradation and storage conditions, guaranteeing the long-term effectiveness and reliability of biologics for clinical applications.

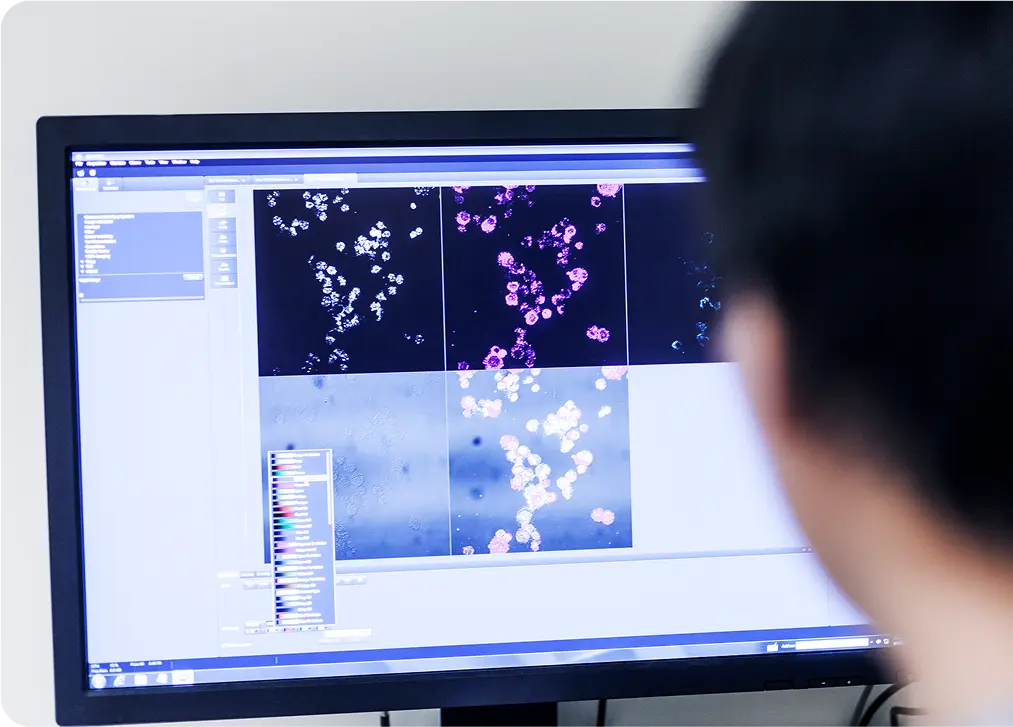

In-Process Testing

We conduct real-time sampling of small-scale cultures to monitor protein production and verify accuracy, ensuring the correct proteins are being expressed at each stage of development.

Final Product Testing

Our rigorous final product assessments evaluate whether the protein meets performance criteria, such as its ability to proliferate cells and its bioavailability, ensuring it functions as intended in therapeutic applications.

Stability & Viability Testing

We perform comprehensive stability testing to assess the protein’s degradation rate, storage conditions, and overall viability, ensuring long-term effectiveness and reliability in research and animal model applications.

Quality Control Assurance

From initial production stages to final product validation, we prioritize accuracy and consistency, performing thorough evaluations to confirm optimal performance and stability. With a focus on functionality, bioavailability, and long-term viability, our testing ensures that each biologic we produce is ready for successful application and meets stringent regulatory requirements.

SCIENTIFIC ADVISORY BOARD

Our Scientific Advisory Board offers critical expertise, providing strategic guidance on emerging trends and novel advancements in the field, ensuring we remain aligned with the latest market developments and scientific innovations.

Relentless innovation that propels breakthroughs in research.

Partner with us to advance your scientific discoveries.